Elevating Efficiency:

How Drones Revolutionize Asset Inspection in the Utilities Sector

By: Richard Armstrong, 1UP Drones Software Engineer – May 2024

Discover how drone technology is transforming asset inspections, offering remarkable cost and time efficiencies compared to traditional methods. This article explores the integration of drones in daily operations, highlighting the reduction in downtime and increase in safety and precision.

In an era where technological advancements are continuously shaping industrial practices, the utility sector stands out for its rapid adoption of drone technology to enhance the efficiency of asset inspections. Traditionally, inspecting utility assets like power lines, wind turbines, and pipelines has been a labor-intensive task that requires significant human resources, time, and exposure to risk. However, with the advent of drone technology, the landscape of routine inspections and maintenance has undergone a transformative shift, offering utility companies an unprecedented ability to streamline operations and improve safety metrics.

Transforming Processes – Traditional vs. Drone Inspections – Wind Turbines Use Case

Drones equipped with high-resolution cameras and other sensory equipment can perform detailed inspections of hard-to-reach assets within minutes. For example, a study by the Electric Power Research Institute highlighted that drone inspections could reduce the manpower and hours needed for wind turbine inspections by about 50% compared to traditional methods. This not only slashes operational costs but also minimizes the downtime of assets during inspection, which can significantly boost productivity and energy output.

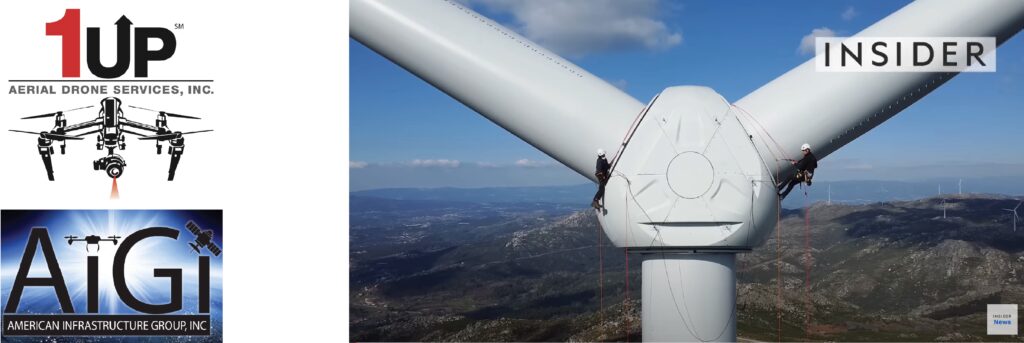

Wind turbine inspections are commonly performed using two methods: rope access with platforms and ground-based inspections using telephoto lenses. Each method has distinct drawbacks. Rope access requires at least three personnel on-site, leading to high labor costs. This approach is also slow, allowing technicians to inspect only one or two turbines daily. Additionally, because the work is conducted at height, there is an increased risk factor, consequently raising insurance costs.

On the other hand, ground-based inspections often suffer from data quality issues. Since the images are taken from the ground at various angles and orientations, certain areas, especially those in shadow or moving rapidly like the tips of the blades, can be poorly captured. Accurately measuring and locating damage is challenging due to the angles involved. Moreover, to capture each side of the blade adequately, extensive camera setup is required, which is time-intensive.

Drones offer several key benefits over traditional inspection methods, including enhanced safety by eliminating the need for workers to operate at dangerous heights, a reduction in inspection times by up to 70%, and the ability to keep wind turbines operational during inspections, avoiding prolonged shutdowns required for manual checks. [3] Drones can conduct comprehensive site assessments or focus on individual wind turbines. Equipped with high-performance cameras, drones can thoroughly inspect a wind turbine’s structure without risking worker safety or necessitating direct access to the turbine.

Traditionally, inspecting a single wind turbine might take between 3 to 6 hours, involving inspectors working at elevated heights. In contrast, advanced RTK drones, which are resistant to wind, can complete the same inspection in approximately 45 minutes. Consequently, a complete inspection of a farm consisting of 15 turbines can be achieved in just three days.

Cost Efficiency and Safety Enhancement

The financial implications of integrating drones into utility inspections are profound. Implementing drone technology can result in substantial cost savings, primarily through reduced labor costs and shorter downtime. Aerial drones eliminate the need for scaffolding, cherry pickers, and other expensive access equipment, which also reduces the risk of workplace accidents. According to a report by PwC, the use of drones in the utilities sector could lead to potential savings of $9.46 billion due to increased efficiency and safety.

Beyond Visual Inspections

Modern drones offer more than just visual inspections. They are equipped with thermal imaging capabilities that can detect overheating parts or connections in electrical installations—issues that are invisible to the naked eye. This capability allows for the early detection of potential failures, preventing costly outages and extending the lifespan of utility assets. Furthermore, drones can be deployed rapidly and frequently, allowing for ongoing monitoring and drastically improving the utility’s ability to manage and maintain its infrastructure proactively.

Case Study: Successful Implementation

Consider the case of a major North American utility that implemented drone technology for routine inspections. The company reported a 55% reduction in inspection time and a 40% drop in costs associated with these inspections. These improvements not only bolstered their operational efficiency but also enhanced worker safety by reducing the need for human presence in potentially hazardous environments.

Looking Forward

As the utility industry continues to evolve, the integration of drone technology in asset inspections is set to become a standard practice, heralded for its efficiency, cost-effectiveness, and safety enhancements. Utility companies that have not yet embraced this technology may find themselves at a competitive disadvantage, unable to optimize operations and cost savings as effectively as their contemporaries.

Drones can be used to inspect the whole turbine from the blades, towers, and nacelles. Inspection techniques include visual, thermographic, acoustic, Lidar, and internal blade inspection. Both autonomous and controlled drones can be used for wind turbine inspection. Using autonomous drones can lead to a 70 to 90 percent drop in inspection and downtime costs. Hours of downtime from lack of regular maintenance or ineffectual inspections can rack up a large financial toll. UAV inspection can shorten the time of inspection to 15 minutes versus an all-day event for the rope access method.

Conclusion – Learn More

At 1UP Drones, we specialize in providing cutting-edge drone technology and expert consulting services tailored to the unique needs of the utility sector. Whether you’re looking to reduce inspection times, enhance safety, or capture precise data with minimal downtime, our solutions are designed to meet and exceed your specialized needs.

Contact us today to discover how our drones and drone services can transform your utility operations. Let 1UP Drones take your asset management to new heights and help you achieve operational excellence in today’s competitive landscape. By leveraging specialized drones equipped for the utilities industry, companies like yours can achieve substantial operational improvements. Make us your trusted drone technology partner — embrace the future today with 1UP Drones.

Visit our website at www.1updrones.com, email info@1updrones.com or give us a call at 972-808-5185. 1UP Drones – Elevating utilities, one flight at a time! 1UP Drones is a proud subsidiary of American Infrastructure Group, Inc. (AIGI).

References

1. Electric Power Research Institute. (2022). Impact of Drone Technology on Wind Turbine Inspections.

2. PwC Report. (2019). Clarity from Above: Drone Applications for Telecommunications and Energy Utilities.

3. Hammer Missions. The Benefits of Using Drones for Inspecting Wind Turbines (2022)

4. DOE Commercial Potential Evaluation (CPE) Report // Drone and Robotic Inspection of Wind Turbines

5. Insider News https://www.youtube.com/watch?v=bNBQKlHt6rg (photo credit & content)