Optimizing Inventory Management:

Drones for Material Tracking on Construction Sites

By: Richard Armstrong, 1UP Drones Software Engineer – May 2024

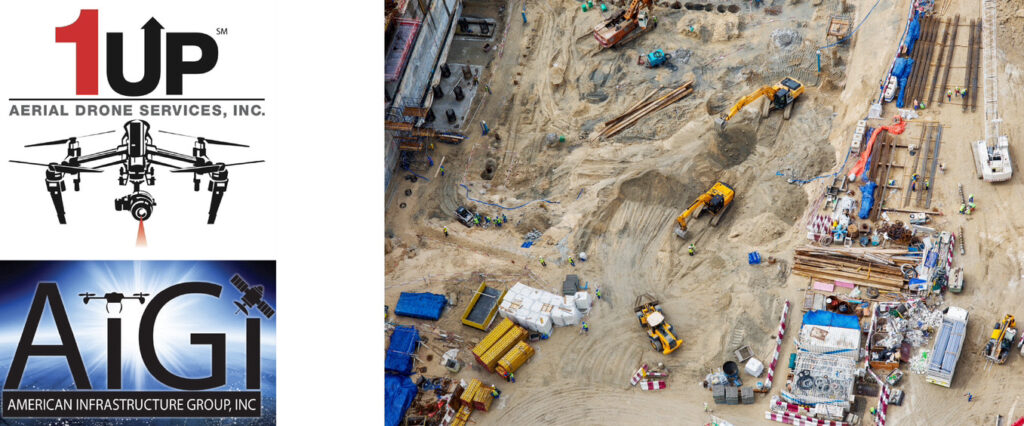

Focused on logistics, this article explores how drones streamline inventory management on construction sites. By deploying drones for aerial surveillance and RFID tagging, construction companies can track materials, equipment, and supplies with precision and efficiency. This piece highlights how drones optimize inventory control, reduce stockpiling costs, and enhance overall project productivity.

In the fast-paced world of construction, efficient logistics management stands as a cornerstone of project success. Amidst the intricate web of materials, equipment, and supplies, the challenge of inventory management looms large, often posing significant logistical hurdles for construction companies. Construction projects can face several challenges in managing inventory across increasingly sprawling project sites. Manual tracking methods are time-consuming, error-prone, and lack real-time visibility into inventory movements. Moreover, the sheer scale and complexity of most projects make it quite challenging to maintain accurate records of materials and supplies, leading to inefficiencies and delays.

However, amidst this complexity, a beacon of innovation emerges: drones. With their aerial surveillance capabilities and RFID tagging technology, drones are revolutionizing material tracking on construction sites, ushering in a new era of efficiency and productivity.

Unlocking Precision and Efficiency Through Aerial Surveillance

Traditionally, inventory management on construction sites has been a manual and labor-intensive process, relying on human oversight and physical inspections. However, the integration of drones introduces a paradigm shift, enabling aerial surveillance that transcends the limitations of traditional methods. Equipped with high-definition cameras and advanced imaging sensors, drones soar above construction sites, providing real-time visibility into inventory levels and asset locations with unprecedented precision and efficiency.

Harnessing RFID Tagging Technology for Enhanced Visibility

Construction implemented RFID technology in collaboration with drone-enabled aerial surveillance is the innovative solution. RFID tags are affixed to key inventory items, including construction materials, equipment, and tools, enabling seamless tracking throughout the supply chain. By affixing RFID tags to inventory items, construction firms can create a digital footprint that enables seamless tracking throughout the supply chain. As drones traverse construction sites, RFID readers onboard scan and capture data from RFID tags, providing real-time insights into inventory movements and locations.

Optimizing Inventory Control and Reducing Stockpiling Costs

The deployment of drones for material tracking on construction sites offers a myriad of benefits, chief among them being the optimization of inventory control. By maintaining accurate and up-to-date records of inventory levels and locations, drones enable construction companies to minimize stockpiling, reduce excess inventory, and avoid costly delays associated with material shortages or overstocking. The use of drones for inventory management could lead to a reduction in excess inventory by as much as 20-25%, resulting in significant cost savings and improved resource utilization.

Enhancing Project Productivity and Driving Operational Excellence

Beyond the realm of inventory management, drones play a pivotal role in enhancing project productivity and driving operational excellence on construction sites. By streamlining material tracking processes and providing real-time visibility into inventory movements, drones enable construction companies to optimize resource allocation, streamline workflows, and minimize downtime. The use of drones for material tracking can lead to a reduction in downtime by as much as 15-20%, allowing construction projects to stay on schedule and within budget.

Embracing a Future of Efficiency and Innovation

As construction companies navigate the complexities of modern-day projects, the integration of drones for material tracking represents a transformative step towards efficiency and innovation. By leveraging aerial surveillance and RFID tagging technology, construction firms can optimize inventory control, reduce stockpiling costs, and enhance overall project productivity. As we embrace a future where efficiency reigns supreme, let us harness the power of drones to streamline material tracking and unlock new levels of success in the construction industry.

In conclusion, the adoption of drones for material tracking on construction sites marks a pivotal moment in the evolution of logistics management. By combining aerial surveillance with RFID tagging technology, construction companies can achieve unparalleled visibility and control over their inventory, driving efficiency, reducing costs, and enhancing project productivity. As pioneers in the construction industry, let us embrace this technological revolution and unlock new opportunities for success in the digital age.

To learn more about how 1UP Drones can provide tailored drone services for your construction project and help you solve the challenge of inventory and material tracking, reach out to us today. Let’s embark on a journey towards enhanced efficiency, cost savings, and project success together.

Visit our website at www.1updrones.com, email info@1updrones.com or give us a call at 972-808-5185. Don’t miss out on the future of construction. 1UP Drones – Elevating Construction, one flight at a time! 1UP Drones is a proud subsidiary of American Infrastructure Group, Inc. (AIGI).